BSA3HP Belgtettende Stengeventiler

UTFORSK PRODUKTENE INNEN DENNE KATOGORIEN

Oversikt

BSA3HP er en høykvalitets, utslippsfri, belgtettet stoppventil i karbonstål for trykk opp til PN100 og ASME klasse 600. Ventilen er konstruert for raskt og enkelt vedlikehold for å sikre minimal nedetid i prosessen.

Det innvendige setets "clamp-in-place"-design gjør at setet kan skiftes ut uten spesialverktøy og uten å måtte fjerne ventilen fra ledningen

Technical Information

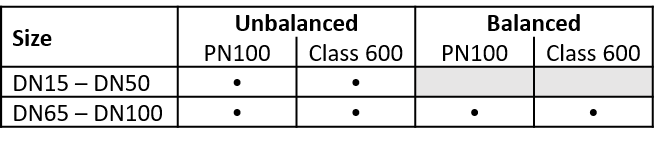

Range and options |

Size and pipe connection |

||

|

|

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80 and DN100. | ||

| Flanged EN 1092 PN100 and ½", ¾", 1", 1¼", 1½", 2", 2½", 3" and 4". | |||

| Flanged ASME class 600 | |||

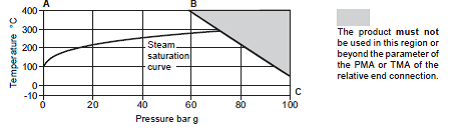

Pressure / temperature limits (ISO 6552) |

|||

A - B - C PN100 |

|||

|

Body design condition | PN100 | |

| PMA Maximum allowable pressure | 100 bar g @ 50 °C | ||

| TMA Maximum allowable temperature | 400 °C @ 59.5 bar g | ||

| Minimum allowable temperature | |||

| PMO Maximum operating pressure for saturated steam service | 70.5 bar g @ 287.3 °C | ||

| TMO Maximum operating temperature | 400 °C @ 59.5 bar g | ||

| Minimum operating temperature | -10 °C | ||

| Designed for a maximum cold hydraulic test pressure of: | 150 bar g | ||

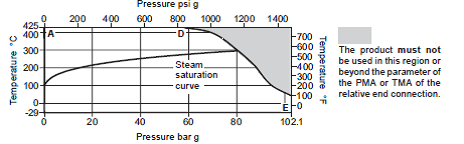

A - D - E Class 600 |

|||

|

Body design condition | Class 600 | |

| PMA Maximum allowable pressure | 102.1 bar g @ 38 °C | 1 481psi g @ 100 °F | |

| TMA Maximum allowable temperature | 425 °C @ 57.5 bar g | 797 °F @ 834 psi g | |

| Minimum allowable temperature | -29 °C | -20 °F | |

| PMO Maximum operating pressure for saturated steam service | 79.8 bar g @ 295.8 °C | 1 156 psi g @ 564.4 °F | |

| TMO Maximum operating temperature | 425 °C @ 57.5 bar g | 797 °F @ 834 psi g | |

| Minimum operating temperature | -29 °C | -20 °F | |

| Designed for a maximum cold hydraulic test pressure of: | 154 bar g | 2 233 psi g | |

Typical Installation

A typical in-line desuperheater installation. A typical desuperheater installation will require isolation valves for both the steam and cooling water pipelines. The BSA3HP is the ideal solution for use on ASME Class 600 rated desuperheater packages.