Bellows Sealed Stop Valves

Explore products in this category

Overview

The Spirax SafeBlocTM is a double isolation solution, with a unique space-saving design, offering reduced installation time and fewer leak paths.

Faster and easier to install than a traditional double block and bleed assembly, the Spirax SafeblocTM has an innovative design which incorporates two bellows sealed isolation valves and a bleed port in one compact assembly.

Easy to use and commission, the Spirax SafeblocTM can be installed without pipework modifications, into the space left by an existing single isolation valve.

Technical Information

Size and pipe connections |

||

|

DN15, DN20, DN25, DN40, DN50, DN65, DN80 and DN100. |

||

|

Flanged EN 1092 PN40 or ANSI B 16.5 Class 300. |

||

|

Face-to-face dimensions conform to BS EN 558:2008. |

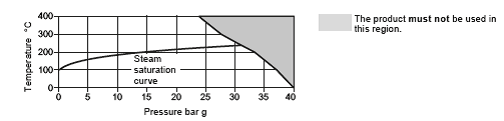

Pressure/temperature limits (ISO 6552) PN40 |

||

|

|

Body design conditions |

PN40 |

|

PMA Maximum allowable pressure |

40 bar g @ 0 °C |

|

|

TMA Maximum allowable temperature |

400 °C @ 24 bar g |

|

|

Minimum allowable temperature |

-10 °C |

|

|

PMO Maximum operating pressure for saturated steam service |

30.4 bar g |

|

|

TMO Maximum operating temperature |

400 °C @ 24 bar g |

|

|

Minimum operating temperature (Note: For lower operating temperatures consult Spirax Sarco) |

-10 °C |

|

|

Designed for a maximum cold hydraulic test pressure of: |

60 bar g |

|

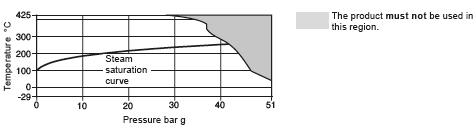

ANSI 300 |

||

|

|

Body design conditions |

ANSI 300 |

|

PMA Maximum allowable pressure |

51 bar g @ 37.7 °C |

|

|

TMA Maximum allowable temperature |

425 °C @ 28 bar g |

|

|

Minimum allowable temperature |

-29 °C |

|

|

PMO Maximum operating pressure for saturated steam service |

41.6 bar g |

|

|

TMO Maximum operating temperature |

425 °C @ 28 bar g |

|

|

Minimum operating temperature (Note: For lower operating temperatures consult Spirax Sarco) |

-29 °C |

|

|

Designed for a maximum cold hydraulic test pressure of: |

77 bar g |

|

Typical Installation

Technical Documentation

Title

Spirax SafeBloc DBB3 Double Block and Bleed Bellows Sealed Stop Valve

language

English

reference number

TI-P184-08

Download

Installation Documentation

Title

Spirax SafeBloc DBB3 Double Block and Bleed Bellows Sealed Stop Valve

language

English

reference number

IM-P184-09