The Boiler House

Contents

Automatic Level Control Systems

A detailed explanation of on/off, modulating, two and three element automatic level control, with a comparison of pros and cons.

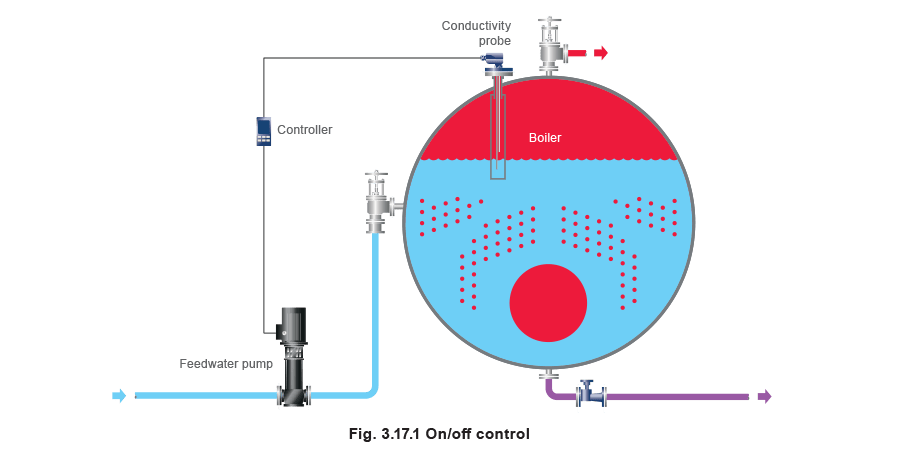

On/off control

All the methods of level detection described so far can be used to produce an on/off signal for level control. The most common method of level control is simply to start the feedpump at a low level and allow it to run until a higher water level is reached within the boiler.

- With a float level control, a magnetic switch with a built-in hysteresis or dead-band will be used.

- With conductivity probes, two probes are necessary, (pump on and pump off) which will give fixed switching levels.

- A capacitance probe can be used to give adjustable on/off switching levels.

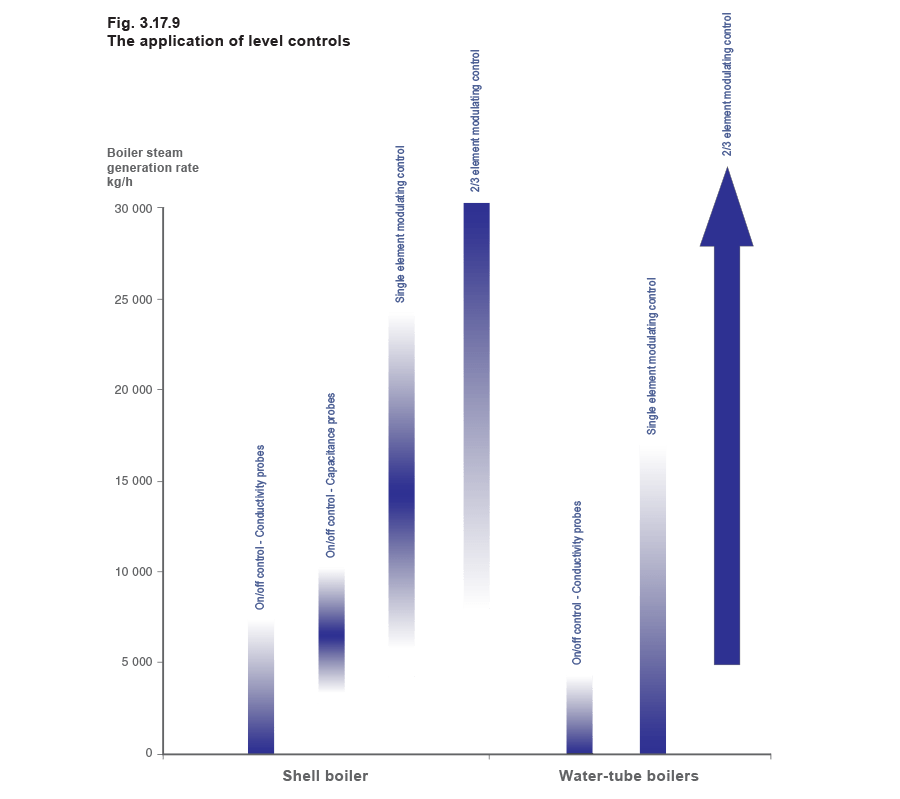

In the UK, on/off type control is almost universal on boilers below about 5 000 kg/h steam generation rate because it is the least expensive option. (In Australia and New Zealand, standards state that for boilers exceeding 3 MW (typically 5 000 kg/h), modulating control must be fitted).

It can be argued, however, that this type of on/off control is not ideal for boiler control, because the relatively high flowrate of ‘cold’ feedwater when the pump is on reduces the boiler pressure.

This causes the burner firing rate to continuously vary as the pump switches on and off.

Taking a typical example, it can be shown by calculation that even with feedwater at 80°C, the burner firing rate may have to be 40% higher with the feedpump on, than with the feedpump off.

This continuous variation causes:

- Wear on the burner controls.

- Temperature cycling of the boiler.

- Reduced efficiency.

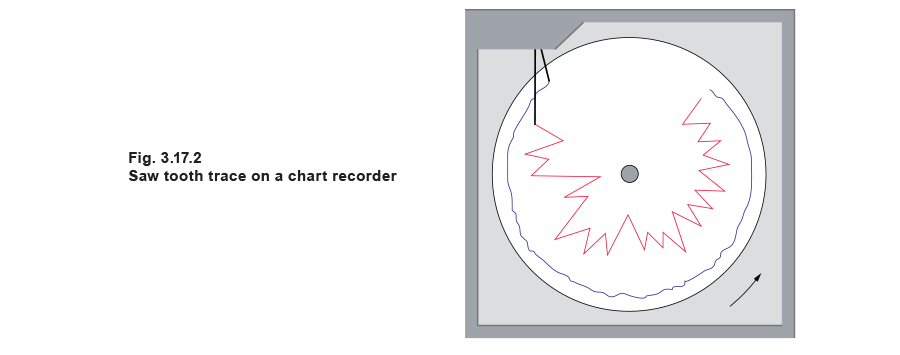

- A ‘saw-tooth’ type steam flowrate as depicted by the chart recorder shown in Figure 3.17.2.

If steam loads are high, the variable steam flowrate will tend to increase water carryover with the steam, and will tend to make water levels increasingly unstable with the associated danger of low water level lockout, particularly on multi-boiler installations.

However, the fact remains that on/off control is very widely used on boilers of small to medium output, as defined above, and that many problems associated with steam boilers operating with large swings in load are due in part to on/off level control systems.

Summary of on/off level control

Advantages:

- Simple.

- Inexpensive.

- Good for boilers on stand-by.

Disadvantages:

- Each boiler requires its own feedpump.

- More wear and tear on the feedpump and control gear.

- Variable steam pressure and flowrate.

- More boiler water carryover.

- Higher chance of daily operating problems under large load swings.

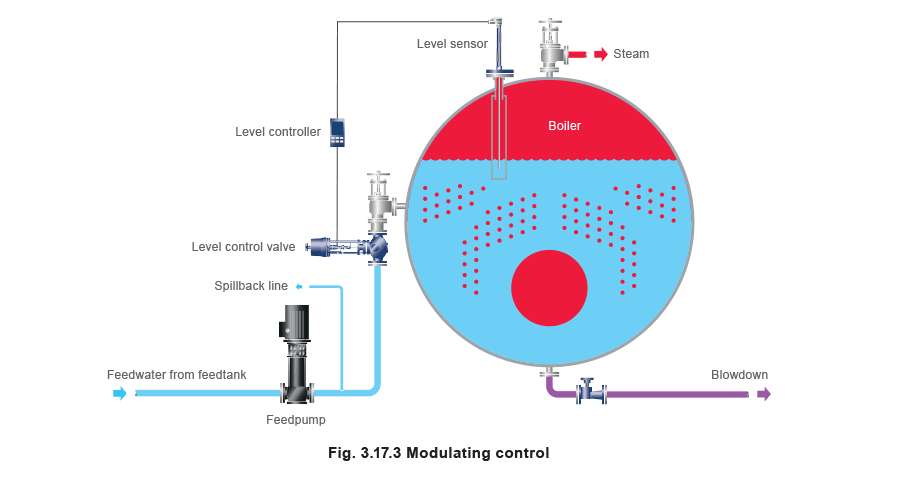

Modulating control

In this type of system the feedpump runs continuously, and an automatic valve (between the feedpump and the boiler) controls the feedwater flowrate to match the steam demand.

When operating correctly, modulating control can dramatically smooth the steam flowrate chart and ensure greater water level stability inside the boiler.

For modulating level control, the following methods can be used to sense the water level:

- Floats with a continuous signal output.

- Capacitance probes.

- Differential pressure cells.

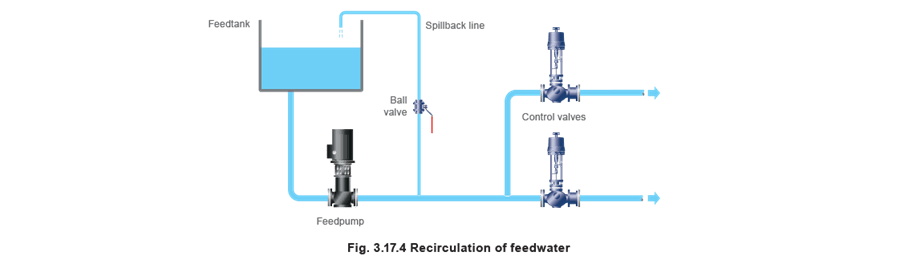

Recirculation

To protect the feedpump from overheating when pumping against a closed modulating valve, a recirculation or spill-back line is provided to ensure a minimum flowrate through the pump.

This recirculation may be controlled by a valve or with an orifice plate. The amount of water to be recirculated is not great, and guidance is usually available from the pump manufacturer. As an indication, the orifice size will usually be between 5 mm and 7 mm for a typical boiler.

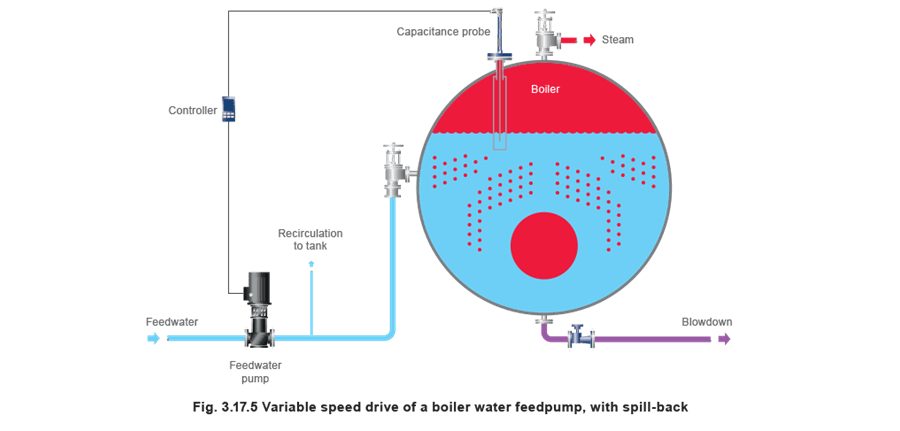

Modulating level control by varying the speed of the boiler feedwater pump

In this type of system, a modulating signal representing boiler water level (for example, from a capacitance probe) is directed to an electrical frequency controller. This controller in turn varies the frequency of the ac voltage to the boiler feedwater pump motor, and hence varies its speed.

- If a lot of water is required, the pump runs at high speed.

- If less water is required, the pump speed is reduced.

In this way the speed of the pump is modulated to provide a feedwater flowrate which matches the boiler’s demand for feedwater.

There are two ways that variable speed drive technology is generally applied:

With recirculation - When demand is satisfied and the motor speed is reduced to its minimum, and some recirculation of feedwater to the feedtank is still required to avoid the pump overheating (see Figure 3.17.5).

Without recirculation - In this case the motor controller stops the feedpump at very low boiler loads, so recirculation is not required.

Two important factors related to stopping and starting of the pump are:

- The pump must not be started and stopped within a given period of time more than is recommended by the manufacturer.

- When starting, the frequency controller should be ramped up from low speed, to minimise wear on the pump.

The principle advantage of variable speed drives is that as the speed of the pump varies, so does its power consumption, and, of course, reduced power consumption means reduced running costs.

However, the cost savings from using variable speed drives must be related to the higher cost of the control equipment. This is usually only viable for large boilers with wide variations in load or which operate in a lead/lag manner.

Single element water level control

The standard single element boiler water level control system, with proportional control, gives excellent control on the majority of boiler installations.

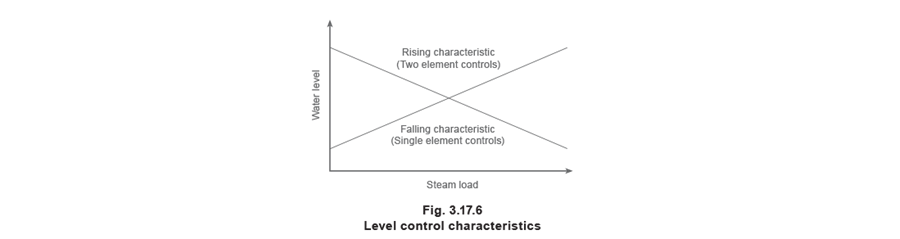

However, with single element proportional control, the water level must fall for the feedwater control valve to open. This means that the water level must be higher at low steaming rates and lower at high steaming rates: a falling level control characteristic.

However, where there are very sudden load changes, on some types of water-tube boiler, single element control has its limitations.

Consider the situation when a boiler is operating within its rated capacity:

- The boiler ‘water’ will actually contain a mixture of water and steam bubbles, which will be less dense than water alone.

- If the demand for steam increases, the pressure in the boiler initially falls, and the control system will increase the burner firing rate. The rate of evaporation will increase to meet the increased demand.

- The increased rate of evaporation means that the boiler water will contain more steam bubbles and become even less dense.

If a sudden load is now applied to the boiler:

- The pressure inside the boiler is further reduced, and a proportion of the boiler water will flash to steam. The flashing of the boiler water, plus the increased heat input as the burners turn up to maximum, means that the boiler ‘water’ will contain even more steam bubbles, and its density will be further reduced.

- As the pressure falls, the specific volume of the steam increases, and the resulting higher velocity at which the steam is drawn off the boiler can create a ‘swell’ of the steam bubble/water mixture, resulting in an apparent rise in water level.

- The level controls will detect this apparent rise in water level, and start to close the feedwater control valve, when in fact more water is required. The situation now, is that there is a high steam demand, and no water is being added to the boiler to maintain the level.

- A point is reached where the ‘swell’ in the water will collapse, possibly to a level below the low level alarms, and the boiler can suddenly ‘lockout’, bringing the plant off-line.

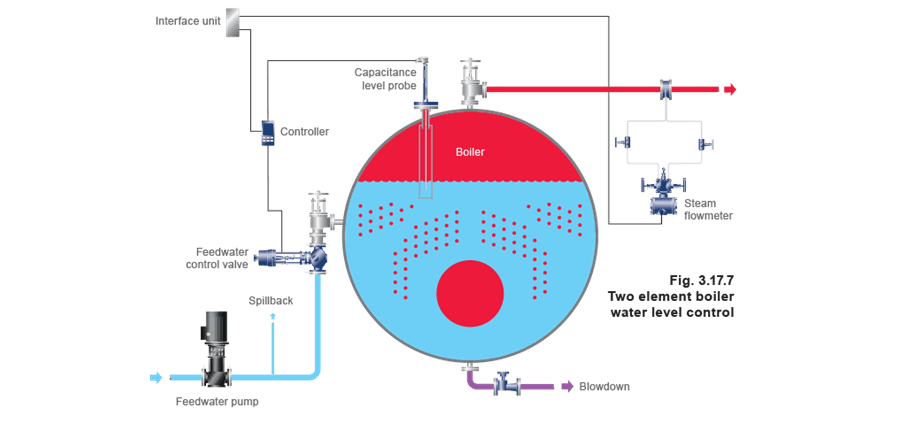

Two element water level control

Two element control reverses the falling level control characteristic to ensure that the water level is made to rise at high steaming rates. This strives to ensure that the quantity of water in the boiler stays constant at all loads, and that during periods of increased, sudden steam demand, the feedwater control valve opens.

The system works by using the signal from a steam flowmeter installed in the steam discharge pipework to increase the level controller set point at high steam loads.

The two elements of the signal are:

- First element - Level signal from the water within the boiler.

- Second element - Flow signal from the steam flowmeter in the boiler steam off-take.

Summary of two element water level control

Any boiler installation which experiences frequent, sudden changes in load may work better with a two element feedwater control system.

Where process load changes are severe (breweries are a common application) two element control should be considered and would appear to be necessary where there are sudden load changes of more than 25%, on a boiler.

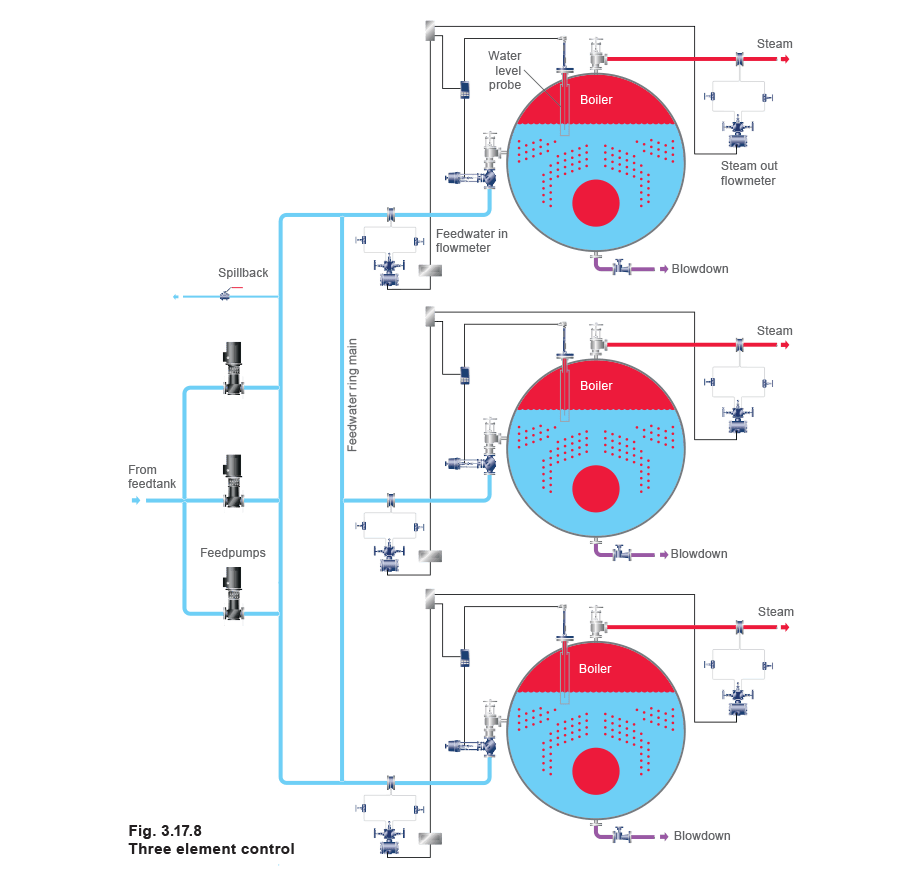

Three element water level control

Three element control as shown in Figure 3.17.8, involves the two signal elements as previously mentioned, plus a third element, which is the actual measured flowrate of feedwater into the boiler. Three element control is more often seen in boiler houses where a number of boilers are supplied with feedwater from a common, pressurised ring main.

Under these circumstances the pressure in the feedwater ring main can vary depending on how much water is being drawn off by each of the boilers.

Because the pressure in the ring main varies, the amount of water which the feedwater control valve will pass will also vary for any particular valve opening. The input from the third element modifies the signal to the feedwater control valve, to take this variation in pressure into consideration.

Summary of modulating level control

Advantages:

- Steady steam pressure and flowrate within the boiler’s thermal capacity.

- More efficient burner operation.

- Less thermal stress on the boiler shell.

- Less boiler water carryover.

- Can use a central feedpump station.

- Less wear and tear on the feedpump and burner.

Disadvantages

- More expensive.

- Feedpump must run continually.

- Less suitable for ‘stand-by’ operation.

- Possibly greater electricity consumption.