Bellows Sealed Stop Valves

Explore products in this category

Overview

The BSA3HP is a high quality, zero emission bellows sealed stop valve in carbon steel for pressure ratings up to PN100 and ASME Class 600. The valve has been engineered to allow fast, easy maintenance to ensure minimal process down-time.

The 'clamp-in-place' design of the internal seat allows the seat to be replaced without special tools and without having to remove the valve from the line.

Technical Information

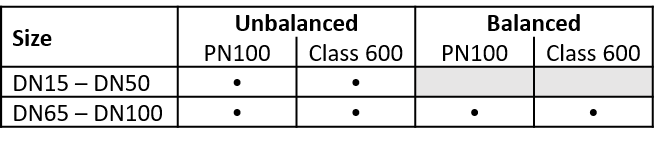

Range and options |

Size and pipe connection |

||

|

|

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80 and DN100. | ||

| Flanged EN 1092 PN100 and ½", ¾", 1", 1¼", 1½", 2", 2½", 3" and 4". | |||

| Flanged ASME class 600 | |||

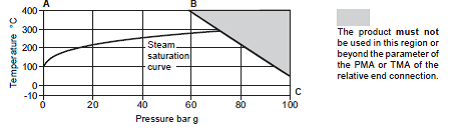

Pressure / temperature limits (ISO 6552) |

|||

A - B - C PN100 |

|||

|

Body design condition | PN100 | |

| PMA Maximum allowable pressure | 100 bar g @ 50 °C | ||

| TMA Maximum allowable temperature | 400 °C @ 59.5 bar g | ||

| Minimum allowable temperature | |||

| PMO Maximum operating pressure for saturated steam service | 70.5 bar g @ 287.3 °C | ||

| TMO Maximum operating temperature | 400 °C @ 59.5 bar g | ||

| Minimum operating temperature | -10 °C | ||

| Designed for a maximum cold hydraulic test pressure of: | 150 bar g | ||

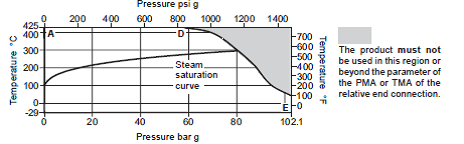

A - D - E Class 600 |

|||

|

Body design condition | Class 600 | |

| PMA Maximum allowable pressure | 102.1 bar g @ 38 °C | 1 481psi g @ 100 °F | |

| TMA Maximum allowable temperature | 425 °C @ 57.5 bar g | 797 °F @ 834 psi g | |

| Minimum allowable temperature | -29 °C | -20 °F | |

| PMO Maximum operating pressure for saturated steam service | 79.8 bar g @ 295.8 °C | 1 156 psi g @ 564.4 °F | |

| TMO Maximum operating temperature | 425 °C @ 57.5 bar g | 797 °F @ 834 psi g | |

| Minimum operating temperature | -29 °C | -20 °F | |

| Designed for a maximum cold hydraulic test pressure of: | 154 bar g | 2 233 psi g | |

Typical Installation

A typical in-line desuperheater installation. A typical desuperheater installation will require isolation valves for both the steam and cooling water pipelines. The BSA3HP is the ideal solution for use on ASME Class 600 rated desuperheater packages.

Technical Documentation

Title

BSA3HP Bellows Sealed High Pressure Stop Valve

language

English

reference number

TI-P184-15

Download

Installation Documentation

Title

BSA3HP Bellows Sealed High Pressure Stop Valve

language

English

reference number

IM-P184-17