Control Hardware Electric-Pneumatic Actuation

Contents

Control Valve Actuators and Positioners

Control valves need actuators to operate. This tutorial briefly discusses the differences between electric and pneumatic actuators, the relationship between direct acting and reverse acting terminology, and how this affects a valve's controlling influence. The importance of positioners is discussed with regard to what they do and why they are required for many applications.

Actuators

In Block 5, ‘Controls Theory’, an analogy was used to describe simple process control:

• The arm muscle and hand (the actuator) turned the valve - (the controlled device).

One form of controlling device, the control valve, has now been covered. The actuator is the next logical area of interest.

The operation of a control valve involves positioning its movable part (the plug, ball or vane) relative to the stationary seat of the valve. The purpose of the valve actuator is to accurately locate the valve plug in a position dictated by the control signal.

The actuator accepts a signal from the control system and, in response, moves the valve to a fully-open or fully-closed position, or a more open or a more closed position (depending on whether ‘on/off’ or ‘continuous’ control action is used).

There are several ways of providing this actuation. This Module will concentrate on the two major ones:

- Pneumatic.

- Electric.

Other significant actuators include the hydraulic and the direct acting types. These are discussed in Block 7, ‘Control Equipment: Self-Acting Controls’.

Pneumatic actuators – operation and options

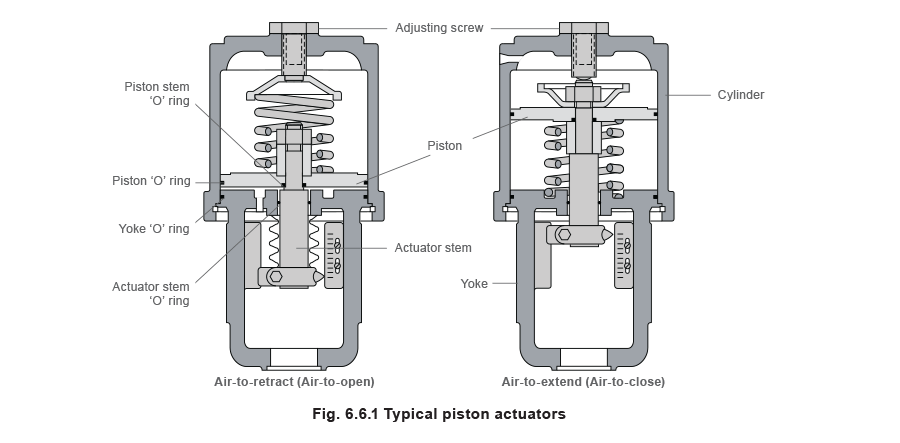

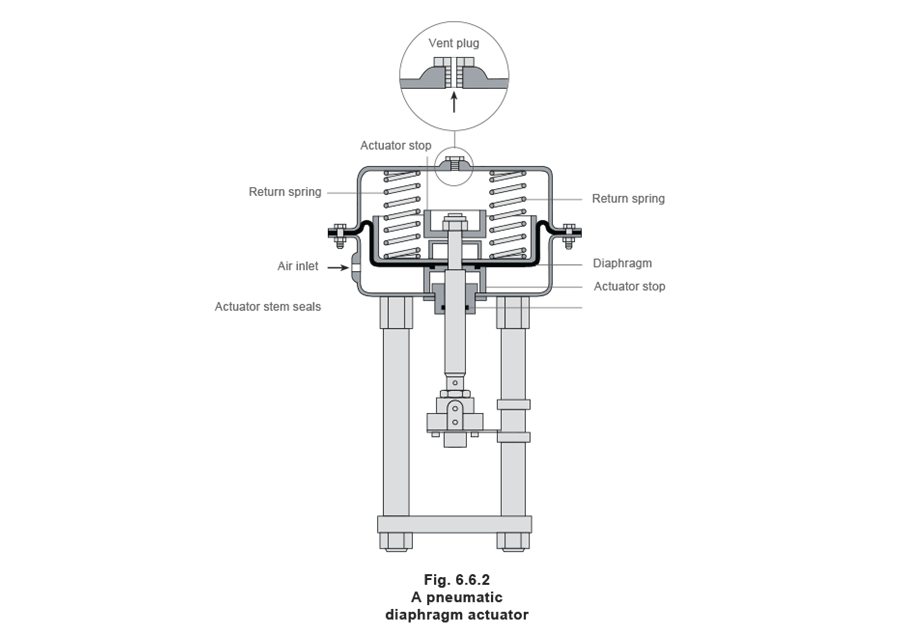

Pneumatic actuators are commonly used to actuate control valves and are available in two main forms; piston actuators (Figure 6.6.1) and diaphragm actuators (Figure 6.6.2)

Piston actuators

Piston actuators are generally used where the stroke of a diaphragm actuator would be too short or the thrust is too small. The compressed air is applied to a solid piston contained within a solid cylinder. Piston actuators can be single acting or double acting, can withstand higher input pressures and can offer smaller cylinder volumes, which can act at high speed.

Diaphragm actuators

Diaphragm actuators have compressed air applied to a flexible membrane called the diaphragm. Figure 6.6.2 shows a rolling diaphragm where the effective diaphragm area is virtually constant throughout the actuator stroke. These types of actuators are single acting, in that air is only supplied to one side of the diaphragm, and they can be either direct acting (spring-to-retract) or reverse acting (spring-to-extend).

Reverse acting (spring-to-extend)

The operating force is derived from compressed air pressure, which is applied to a flexible diaphragm. The actuator is designed so that the force resulting from the air pressure, multiplied by the area of the diaphragm, overcomes the force exerted (in the opposite direction) by the spring(s).

The diaphragm (Figure 6.6.2) is pushed upwards, pulling the spindle up, and if the spindle is connected to a direct acting valve, the plug is opened. The actuator is designed so that with a specific change of air pressure, the spindle will move sufficiently to move the valve through its complete stroke from fully-closed to fully-open.

As the air pressure decreases, the spring(s) moves the spindle in the opposite direction. The range of air pressure is equal to the stated actuator spring rating, for example 0.2 - 1 bar.

With a larger valve and/or a higher differential pressure to work against, more force is needed to obtain full valve movement.

To create more force, a larger diaphragm area or higher spring range is needed. This is why controls manufacturers offer a range of pneumatic actuators to match a range of valves – comprising increasing diaphragm areas, and a choice of spring ranges to create different forces.

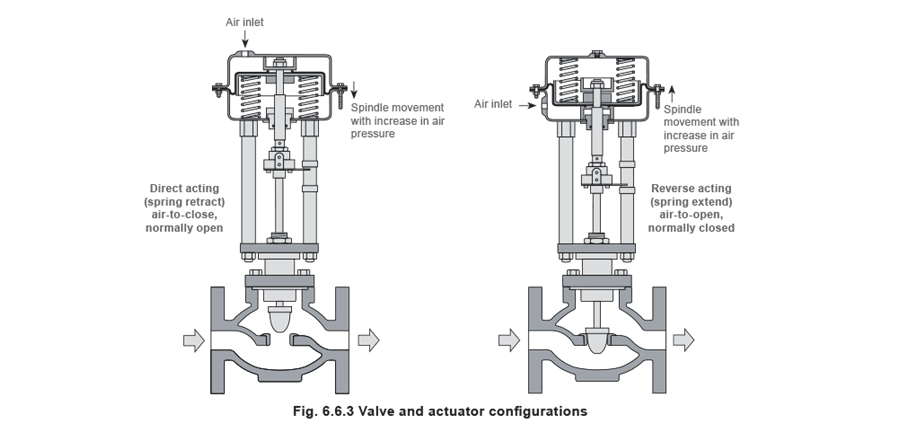

The diagrams in Figure 6.6.3 show the components of a basic pneumatic actuator and the direction of spindle movement with increasing air pressure.

Direct acting actuator (spring-to-retract)

The direct acting actuator is designed with the spring below the diaphragm, having air supplied to the space above the diaphragm. The result, with increasing air pressure, is spindle movement in the opposite direction to the reverse acting actuator.

The effect of this movement on the valve opening depends on the design and type of valve used, and is illustrated in Figure 6.6.3.

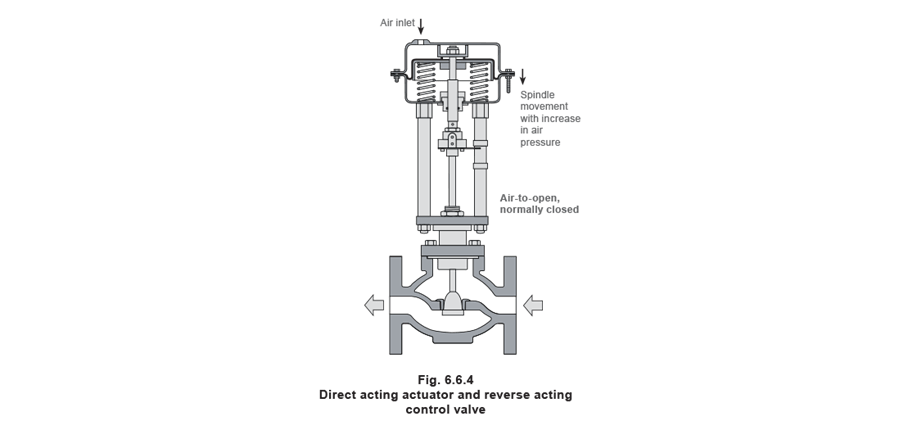

There is however, an alternative, which is shown in Figure 6.6.4. A direct acting pneumatic actuator is coupled to a control valve with a reverse acting plug (sometimes called a ‘hanging plug’).

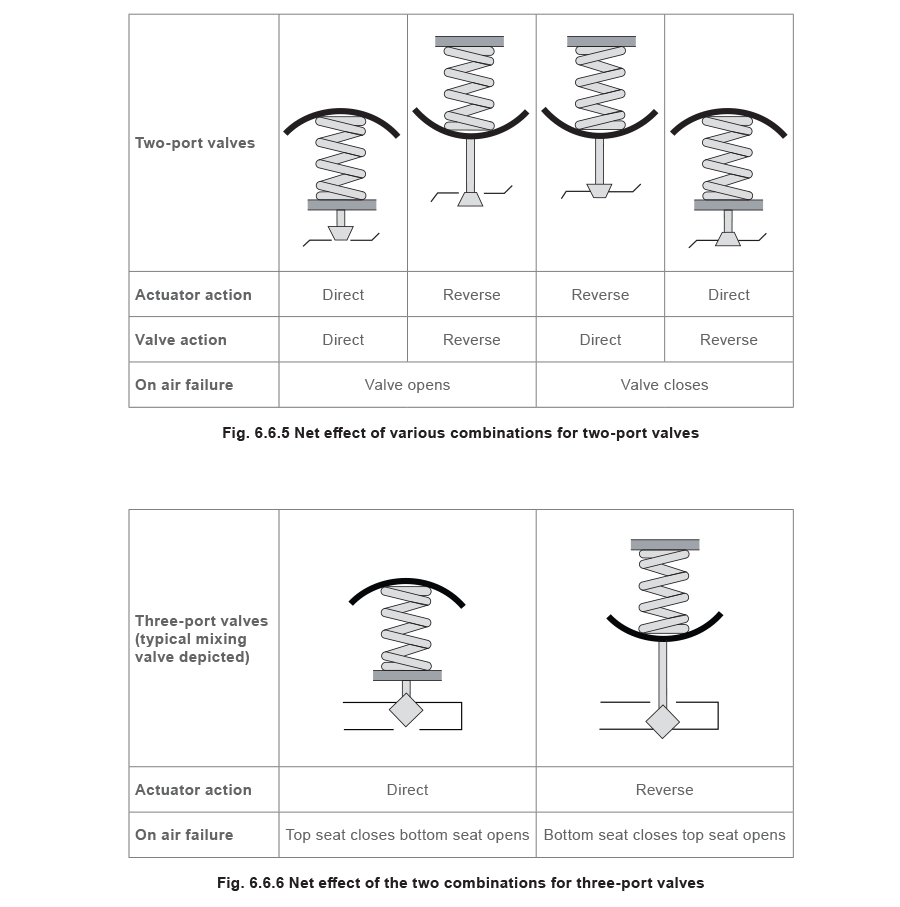

The choice between direct acting and reverse acting pneumatic controls depends on what position the valve should revert to in the event of failure of the compressed air supply. Should the valve close or be wide-open? This choice depends upon the nature of the application and safety requirements. It makes sense for steam valves to close on air failure, and cooling valves to open on air failure. The combination of actuator and valve type must be considered.

Figure 6.6.5 and Figure 6.6.6 show the net effect of the various combinations.

Effect of differential pressure on the valve lift

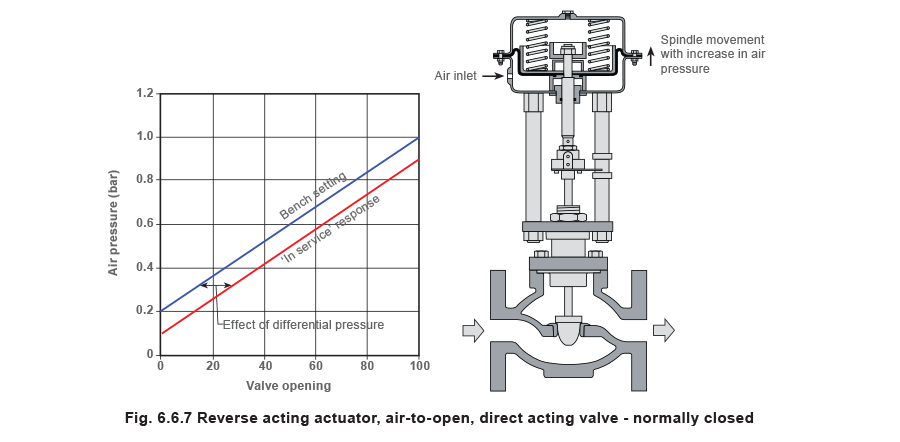

The air fed into the diaphragm chamber is the control signal from the pneumatic controller. The most widely used signal air pressure is 0.2 bar to 1 bar. Consider a reverse acting actuator (spring-to-extend) with standard 0.2 to 1.0 bar spring(s), fitted to a direct acting valve (Figure 6.6.7).

When the valve and actuator assembly is calibrated (or ‘bench set’), it is adjusted so that an air pressure of 0.2 bar will just begin to overcome the resistance of the springs and move the valve plug away from its seat.

As the air pressure is increased, the valve plug moves progressively further away from its seat, until finally at 1 bar air pressure, the valve is 100% open. This is shown graphically in Figure 6.6.7.

Now consider this assembly installed in a pipeline in a pressure reducing application, with 10 bar g on the upstream side and controlling the downstream pressure to 4 bar g.

The differential pressure across the valve is 10 - 4 = 6 bar. This pressure is acting on the underside of the valve plug, providing a force tending to open the valve. This force is in addition to the force provided by the air pressure in the actuator.

Therefore, if the actuator is supplied with air at 0.6 bar (halfway between 0.2 and 1 bar), for example, instead of the valve taking up the expected 50% open position, the actual opening will be greater, because of the extra force provided by the differential pressure.

Also, this additional force means that the valve is not closed at 0.2 bar. In order to close the valve in this example, the control signal must be reduced to approximately 0.1 bar.

The situation is slightly different with a steam valve controlling temperature in a heat exchanger, as the differential pressure across the valve will vary between:

- A minimum, when the process is calling for maximum heat, and the control valve is 100% open.

- A maximum, when the process is up to temperature and the control valve is closed.

The steam pressure in the heat exchanger increases as the heat load increases. This can be seen in Module 6.5, Example 6.5.3 and Table 6.5.7.

If the pressure upstream of the control valve remains constant, then, as the steam pressure rises in the heat exchanger, the differential pressure across the valve must decrease.

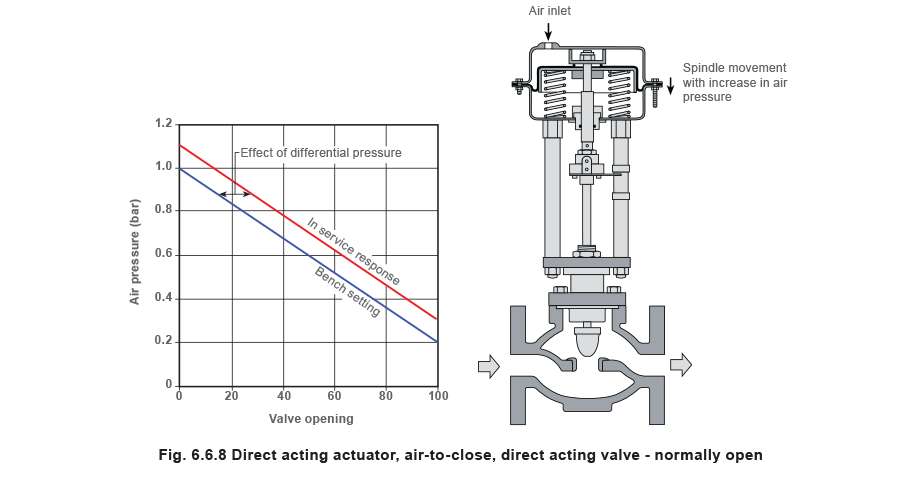

Figure 6.6.8 shows the situation with the air applied to a direct acting actuator. In this case, the force on the valve plug created by the differential pressure works against the air pressure. The effect is that if the actuator is supplied with air at 0.6 bar, for example, instead of the valve taking up the expected 50% open position, the percentage opening will be greater because of the extra force provided by the differential pressure. In this case, the control signal has to be increased to approximately 1.1. bar to fully close the valve.

It may be possible to recalibrate the valve and actuator to take the forces created by differential pressure into account, or perhaps using different springs, air pressure and actuator combinations. This approach can provide an economic solution on small valves, with low differential pressures and where precise control is not required. However, the practicalities are that:

- Larger valves have greater areas for the differential pressure to act over, thus increasing the forces generated, and having an increasing effect on valve position.

- Higher differential pressures mean that higher forces are generated.

- Valves and actuators create friction, causing hysteresis. Smaller valves are likely to have greater friction relative to the total forces involved.

The solution is to fit a positioner to the valve/actuator assembly. (More information is given on positioners later in this Module).

Note: For simplicity, the above examples assume a positioner is not used, and hysteresis is zero.

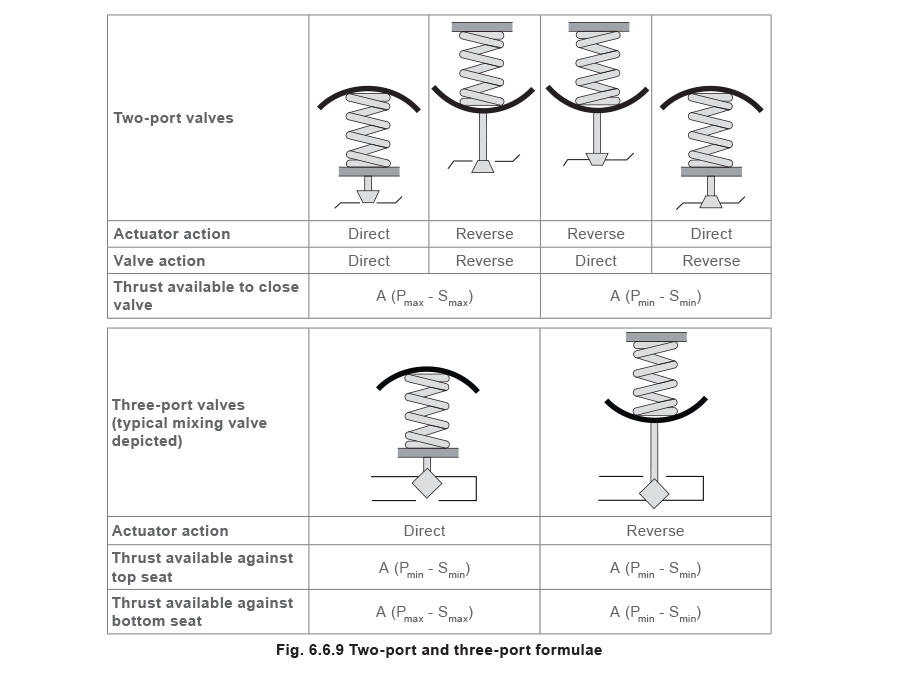

The formulae used to determine the thrust available to hold a valve on its seat for various valve and actuator combinations are shown in Figure 6.6.9.

Where:

A = Effective area of diaphragm

Pmax = Maximum pressure to actuator (normally 1.2 bar)

Smax = Maximum bench setting of spring

Pmin = Minimum pressure to actuator (normally 0 bar)

Smin = Minimum bench setting of spring

The thrust available to close the valve has to provide three functions:

- To overcome the fluid differential pressure at the closed position.

- To overcome friction in the valve and actuator, primarily at the valve and actuator stem seals.

- To provide a sealing load between the valve plug and valve seat to ensure the required degree of tightness.

Control valve manufacturers will normally provide full details of the maximum differential pressures against which their various valve and actuator/spring combinations will operate; the Table in Figure 6.6.10 is an example of this data.

Note: When using a positioner, it is necessary to refer to the manufacturer’s literature for the minimum and maximum air pressures.

Positioners

For many applications, the 0.2 to 1 bar pressure in the diaphragm chamber may not be enough to cope with friction and high differential pressures. A higher control pressure and stronger springs could be used, but the practical solution is to use a positioner.

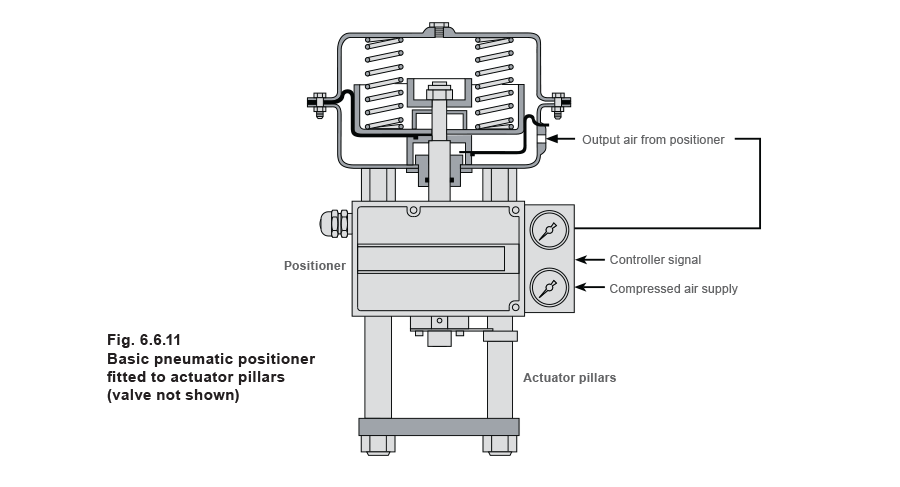

This is an additional item (see Figure 6.6.11), which is usually fitted to the yoke or pillars of the actuator, and it is linked to the spindle of the actuator by a feedback arm in order to monitor the valve position. It requires its own higher-pressure air supply, which it uses to position the valve.

A valve positioner relates the input signal and the valve position, and will provide any output pressure to the actuator to satisfy this relationship, according to the requirements of the valve, and within the limitations of the maximum supply pressure.

When a positioner is fitted to an ‘air-to-open’ valve and actuator arrangement, the spring range may be increased to increase the closing force, and hence increase the maximum differential pressure a particular valve can tolerate. The air pressure will also be adjusted as required to overcome friction, therby reducing hysteresis effects.

Example: Taking a PN5400 series actuator fitted to a DN50 valve (see Table in Figure 6.6.10)

- With a standard 0.2 to 1.0 bar spring range (PN5420), the maximum allowable differential pressure is 3.0 bar.

- With a 1.0 to 2.0 bar spring set (PN5426), the maximum allowable differential pressure is increased to 13.3 bar.

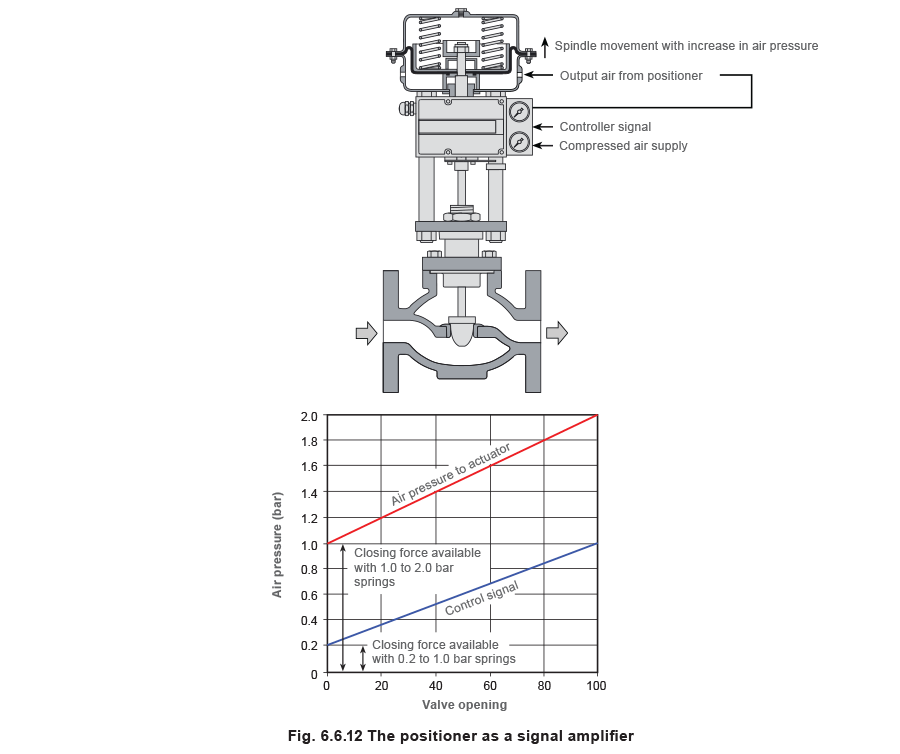

With the second option, the 0.2 to 1.0 bar signal air pressure applied to the actuator diaphragm cannot provide sufficient force to move an actuator against the force provided by the 1.0 to 2.0 bar springs, and even less able to control it over its full operating range. In these circumstances the positioner acts as an amplifier to the control signal, and modulates the supply air pressure, to move the actuator to a position appropriate to the control signal pressure.

For example, if the control signal was 0.6 bar (50% valve lift), the positioner would need to allow approximately 1.5 bar into the actuator diaphragm chamber. Figure 6.6.12 illustrates this relationship.

It should be noted that a positioner is a proportional device, and in the same way that a proportional controller will always give an offset, so does a positioner.

On a typical positioner, the proportional band may be between 3 and 6%. The positioner sensitivity can usually be adjusted. It is essential that the installation and maintenance instructions be read prior to the commissioning stage.

Summary - Positioners

- A positioner ensures that there is a linear relationship between the signal input pressure from the control system and the position of the control valve. This means that for a given input signal, the valve will always attempt to maintain the same position regardless of changes in valve differential pressure, stem friction, diaphragm hysteresis and so on.

- A positioner may be used as a signal amplifier or booster. It accepts a low pressure air control signal and, by using its own higher pressure input, multiplies this to provide a higher pressure output air signal to the actuator diaphragm, if required, to ensure that the valve reaches the desired position.

- Some positioners incorporate an electropneumatic converter so that an electrical input (typically 4 - 20 mA) can be used to control a pneumatic valve.

- Some positioners can also act as basic controllers, accepting input from sensors.

A frequently asked question is, ‘When should a positioner be fitted?’

A positioner should be considered in the following circumstances:

- When accurate valve positioning is required.

- To speed up the valve response. The positioner uses higher pressure and greater air flow to adjust the valve position.

- To increase the pressure that a particular actuator and valve can close against. (To act as an amplifier).

- Where friction in the valve (especially the packing) would cause unacceptable hysteresis.

- To linearise a non-linear actuator.

- Where varying differential pressures within the fluid would cause the plug position to vary

To ensure that the full valve differential pressure can be accepted, it is important to adjust the positioner zero setting so that no air pressure opposes the spring force when the valve is seating.

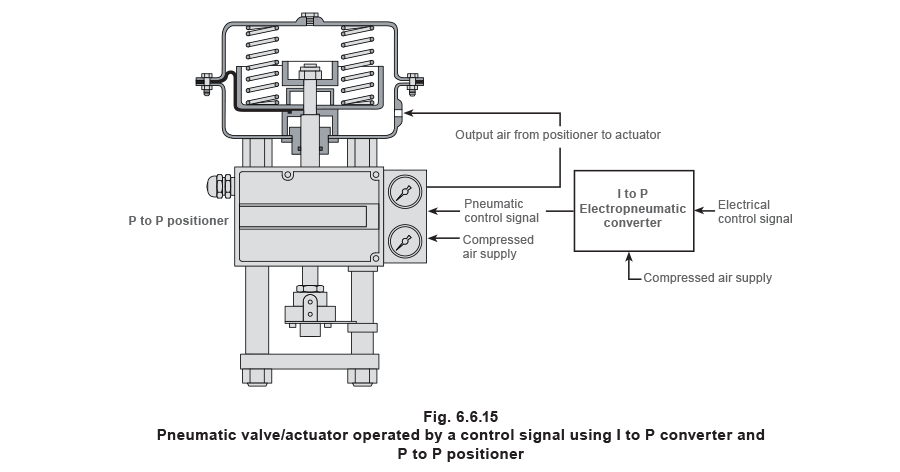

Figure 6.6.13 shows a typical positioner. Commonly, this would be known as a P to P positioner since it takes a pneumatic signal (P) from the control system and provides a resultant pneumatic output signal (P) to move the actuator.

One advantage of a pneumatic control is that it is intrinsically safe, i.e. there is no risk of explosion in a dangerous atmosphere, and it can provide a large amount of force to close a valve against high differential pressure. However, pneumatic control systems themselves have a number of limitations compared with their electronic counterparts.

To alleviate this, additional components are available to enable the advantages of a pneumatic valve and actuator to be used with an electronic control system.

The basic unit is the I to P converter. This unit takes in an electrical control signal, typically 4 - 20 mA, and converts it to a pneumatic control signal, typically 0.2 - 1 bar, which is then fed into the actuator, or to the P to P positioner, as shown in Figure 6.6.15.

With this arrangement, an I to P (electrical to pneumatic) conversion can be carried out outside any hazardous area, or away from any excessive ambient temperatures, which may occur near the valve and pipeline.

However, where the conditions do not present such problems, a much neater solution is to use a single component electropneumatic converter/positioner, which combines the functions of an I to P converter and a P to P positioner, that is a combined valve positioner and electropneumatic converter. Figure 6.6.16 shows a typical I to P converter/positioner.

Most sensors still have analogue outputs (for example 4 - 20 mA or 0 - 10 V), which can be converted to digital form. Usually the controller will perform this analogue-to-digital (A/D) conversion, although technology is now enabling sensors to perform this A/D function themselves. A digital sensor can be directly connected into a communications system, such as Fieldbus, and the digitised data transmitted to the controller over a long distance. Compared to an analogue signal, digital systems are much less susceptible to electrical interference.

Analogue control systems are limited to local transmission over relatively short distances due to the resistive properties of the cabling.

Most electrical actuators still require an analogue control signal input (for example 4 - 20 mA or 0 - 10 V), which further inhibits the completion of a digital communications network between sensors, actuators, and controllers.

Digital positioners

Sometimes referred to as a SMART positioner, the digital positioner monitors valve position, and converts this information into a digital form. With this information, an integrated microprocessor offers advanced user features such as:

- High valve position accuracy.

- Adaptability to changes in control valve condition.

- Many digital positioners use much less air than analogue types.

- An auto stroking routine for easy setting-up and calibration.

- On-line digital diagnostics.*

- Centralised monitoring.*

*Using digital communications protocols such as HART® ; Fieldbus, or Profibus.

The current industrial trend is to provide equipment with the capability to communicate digitally with networked systems in a Fieldbus environment. It is widely thought that digital communications of this type offer great advantages over traditional analogue systems.

Selecting a pneumatic valve and actuator

In summary, the following is a list of the major factors that must be considered when selecting a pneumatic valve and actuator:

- Select a valve using the application data.

- Determine the valve action required in the event of power failure, fail-open or fail-closed.

- Select the valve actuator and spring combination required to ensure that the valve will open or close against the differential pressure.

- Determine if a positioner is required.

- Determine if a pneumatic or electric control signal is to be provided. This will determine whether an I to P converter or, alternatively a combined I to P converter / positioner, is required.

Rotary pneumatic actuators and positioners

Actuators are available to drive rotary action valves, such as ball and butterfly valves. The commonest is the piston type, which comprises a central shaft, two pistons and a central chamber all contained within a casing. The pistons and shaft have a rack and pinion drive system.

In the simplest types, air is fed into the central chamber (Figure 6.6.18a), which forces the pistons outwards.

The rack and pinion arrangement turns the shaft and, because the latter is coupled to the valve stem, the valve opens or closes.

When the air pressure is relieved, movement of the shaft in the opposite direction occurs due to the force of the return springs (Figure 6.6.18b).

It is also possible to obtain double acting versions, which have no return springs. Air can be fed into either side of the pistons to cause movement in either direction. As with diaphragm type actuators, they can also be fitted with positioners.

Air supply

An adequate compressed air supply system is essential to provide clean and dry air at the right quantity and pressure. It is advantageous to install an individual coalescing filter/regulator unit ahead of the final supply connection to each piece of equipment. Air quality is particularly important for pneumatic instrumentation such as controllers, I to P convertors and positioners.

The decision to opt for a pneumatically operated system may be influenced by the availability and/or the costs to install such a system. An existing air supply would obviously encourage the use of pneumatically powered controls.

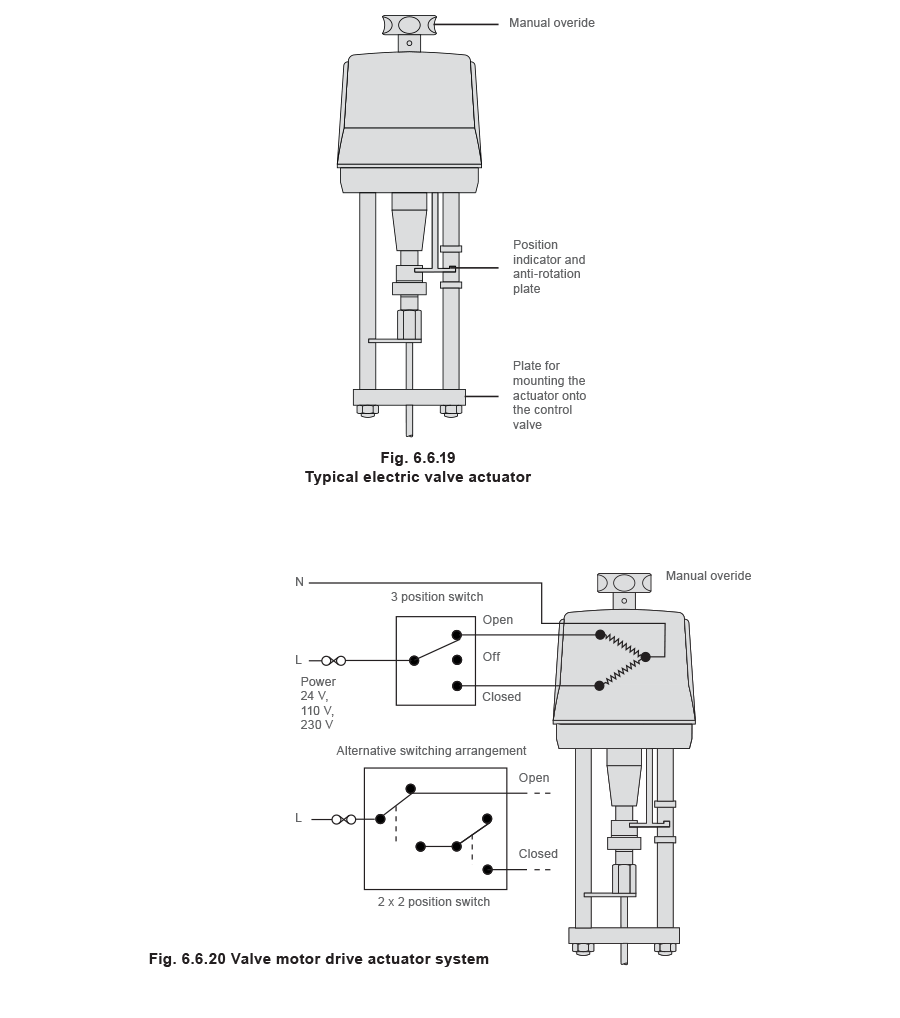

Electrical actuators

Where a pneumatic supply is not available or desirable it is possible to use an electric actuator to control the valve. Electric actuators use an electric motor with voltage requirements in the following range: 230 Vac, 110 Vac, 24 Vac and 24 Vdc.

There are two types of electrical actuator; VMD (Valve Motor Drive) and Modulating.

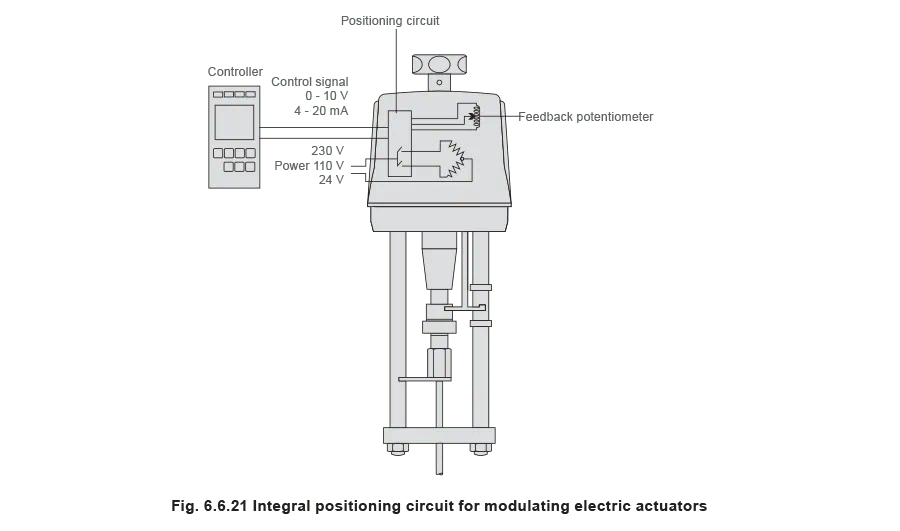

VMD (Valve Motor Drive)

This basic version of the electric actuator has three states:

- Driving the valve open.

- Driving the valve closed.

- No movement.

Figure 6.6.20 shows the VMD system where the forward and reverse travel of the actuator is controlled directly from any external 3-position or two 2-position switch units. The switches are rated at the actuator voltage and may be replaced by suitable relays.

Limiting devices are fitted within the VMD actuators to protect the motors from over-travel damage. These devices are based on either the maximum motor torque or physical position limit switches. Both devices stop the motor driving by interrupting the motor power supply.

- Position limit switches have the advantage that they can be adjusted to limit valve strokes in oversized valves.

- Torque switches have the advantage of giving a defined closing force on the valve seat, protecting the actuator in the case of valve stem seizure.

- If only position limit switches are used, they may be combined with a spring-loaded coupling to ensure tight valve shut-off.

A VMD actuator may be used for on/off actuation or for modulating control. The controller positions the valve by driving the valve open or closed for a certain time, to ensure that it reaches the desired position. Valve position feedback may be used with some controllers

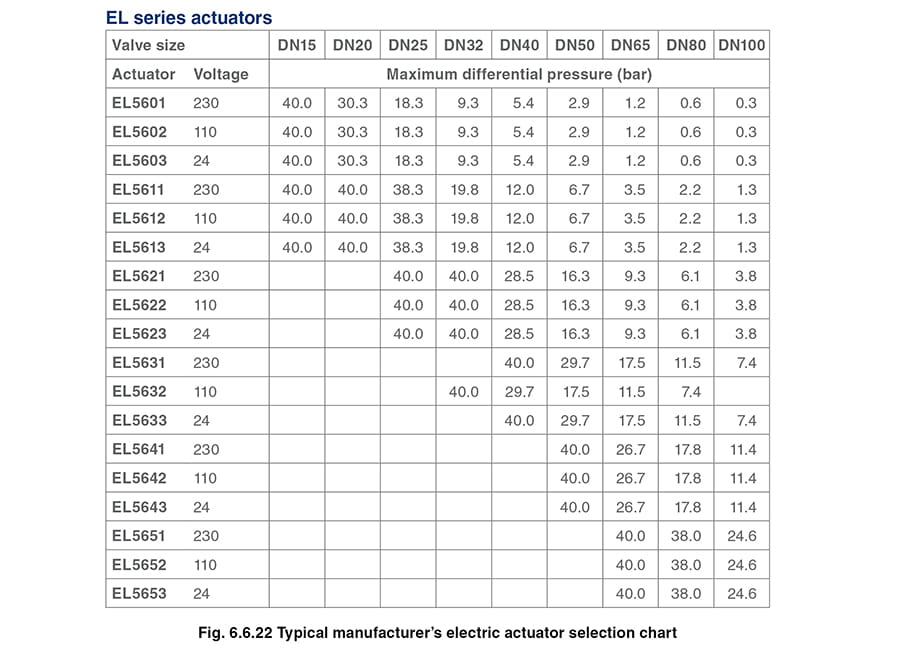

Modulating

In order to position the control valve in response to the system requirements a modulating actuator can be used. These units may have higher rated motors (typically 1 200 starts/hour) and may have built-in electronics.

A positioning circuit may be included in the modulating actuator, which accepts an analogue control signal (typically 0-10 V or 4-20 mA). The actuator then interprets this control signal, as the valve position between the limit switches.

To achieve this, the actuator has a position sensor (usually a potentiometer), which feeds the actual valve position back to the positioning circuit. In this way the actuator can be positioned along its stroke in proportion to the control signal. A schematic of the modulating actuator is shown in Figure 6.6.21..

Pneumatic actuators have an inherent fail-safe feature; should the air supply or control signal fail the valve will close. To provide this function in electric actuators, ‘spring reserve’ versions are available which will open or close the valve on power or control signal failure. Alternatively, fail-safe can be provided with battery power.

Electric actuators offer specified forces, which may be limited on spring reserve versions. The manufacturer’s charts should always be consulted during selection.

When sizing an actuator, it is wise to refer to the manufacturer’s technical data sheets for maximum differential pressure across the valve (see Figure 6.6.22).

Another limitation of an electric actuator is the speed of valve movement, which can be as low as 4 seconds/mm, which in rapidly varying systems may be too slow.