01/08/2022

For hospital managers responsible for the safe sterilisation of reusable instruments, re-processing because of wet packs is a time consuming headache.

This blog explores the causes of wet packs and what can be done to prevent them. We have also created a Steam Quality Validation paper to help you understand where to sample, the number of sampling points needed, as well as validation and periodic testing.

So what causes Wet Packs and what can be done about them?

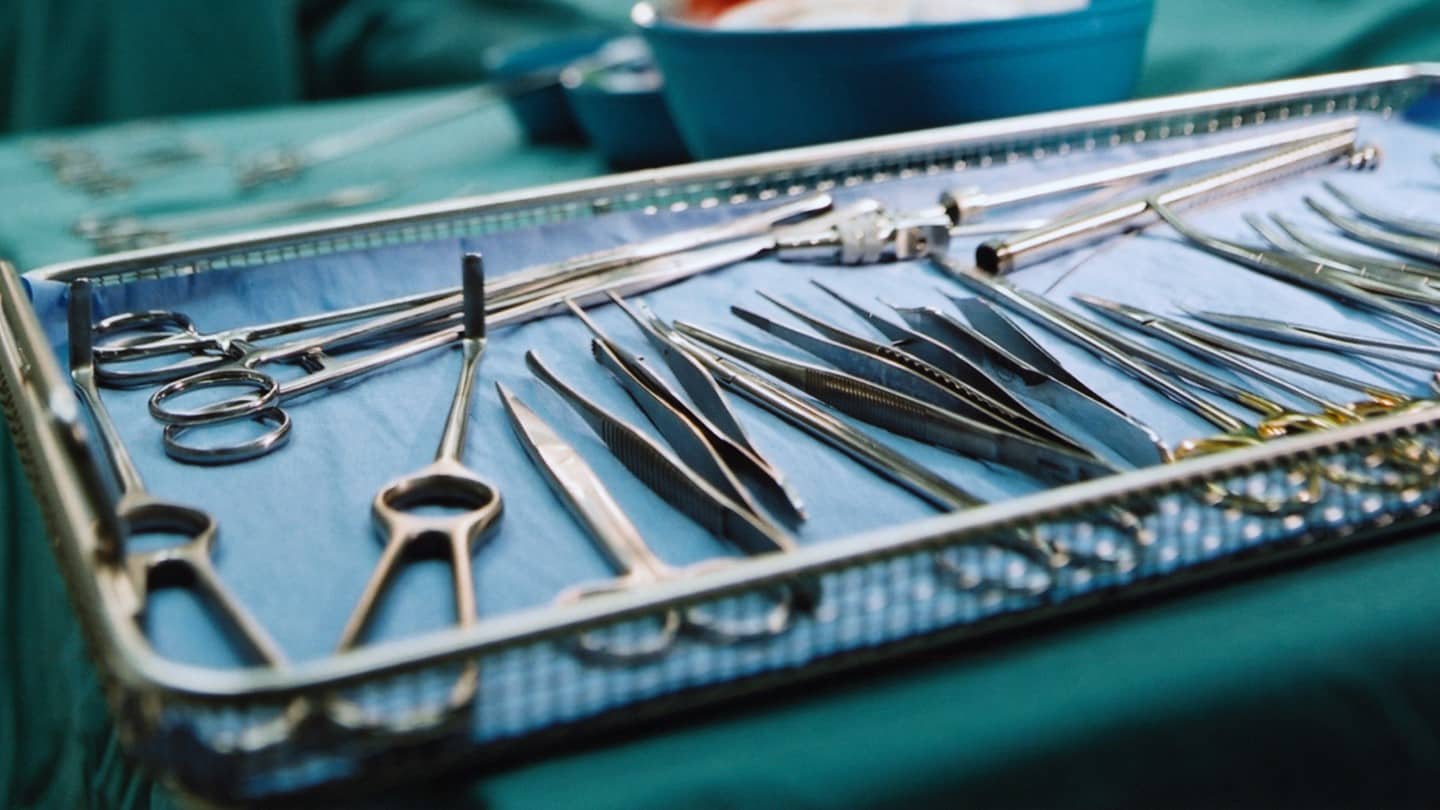

Sterilisation using steam is by far the most common process for sterilising reusable medical instruments and devices. Ensuring that the sterilisation process is efficient and safe is key to patient safety in hospitals around the globe.

Hospital Sterile Services and Decontamination units provide frontline defence against disease-causing bacteria which can flourish in air and water.

To be certain something is sterile you need a ‘state of dryness’. Wet materials carry bacteria, so a ‘state of wetness’ compromises the sterility of processed packs and instruments.

A common misconception is that water is also sterile and therefore there is no risk of contamination, this is incorrect. Even if the packs are left to dry, the water can create a pathway for microorganisms to penetrate the packs.Learn how to prevent this and only sterilise once Access the white paper

‘Wet packs’ have long been a major concern for the medical profession, where having sterile items is essential. When packs must be re-sterilised, there are costs in time and money, with potentially serious impacts on departments’ efficiency.

One wet pack is trouble enough. When you have more than one pack with moisture either outside or inside the pack, it’s a wet load and everything must undergo the procedure again.

What causes wet packs and loads in sterilisation?

Finding out that you have a wet pack issue is only the start of your problems. There is a multitude of factors that will need to be looked at, individually, to pinpoint the cause of your wet pack issues.

If you find moisture on the outside of a package, the most common culprits are likely moisture coming into the chamber through the steam lines, or metal items on a shelf above dripping condensate onto the items below.

When it’s moisture inside a package, this is often due to how the autoclave has been loaded or overloaded. This internal moisture can wick its way through to the outside of the pack, again allowing microorganisms to enter.

Whilst it’s widely agreed that improperly prepared and loaded items are a major cause of wet packs, finding where things are not being done correctly isn’t always simple. That’s why the first step in investigating the problem has to be methodical documentation of when wet packs occur.

Carry out an audit of everything being readied by your staff. Are they fully aware of the implications of wet packs in your organisation, and how carefully following directions can help reduce them?

Once you are certain that your wet pack problems do not stem from poor technique, you can turn your attention to other issues.

Why is steam quality important in medical sterilisation?

Check to see if good quality steam is being provided for the steam sterilisation process. It’s vital to remember that you will only achieve effective, safe sterilisation if the steam quality is made up of 97% saturated steam with no greater than 3% liquid content. Any more liquid content will lead to steam that is too wet, and, of course, more wet packs.

Take, for example, a load which sometimes has wetness on the outside of the packs in the upper back quarter of the load with the rest staying dry. The port where the steam comes into the chamber is right next to that wet area. In this case, a possible cause for the dampness in this region is down to poor steam quality, which can be due to several different factors.

Poor steam quality might be down to excessive demand on the boiler, uninsulated pipes, or improperly trapped lines. You may only find the issue with wet packs happens at times the boiler is at peak use, and so only happen now and again. Alternatively, wet packs may be an ongoing issue for you.

Why clean steam may be the answer to eliminating wet packs?

Finding out where there are issues with your steam supply, and how it’s linked to your Sterile Services Department, is complicated. There are many points where problems may be hindering your sterilisation process.

Both an accurate test of your steam quality, and a steam audit are recommended to eliminate these factors from your investigation.

The actual source of your steam, especially if that is from the main boiler function of the facility, should be a focus for you. In these cases, steam quality can vary greatly during a working day.

In many hospitals, demand for steam is greatest early in the morning when SSDs, laundries, kitchens, and hot water are in great demand.

Often a central supply cannot deliver steam of acceptable standard, and improvements in operating practice and engineering modifications may need to be extensive to rectify the issues. In many cases the installation of a purpose-built steam generator solely to supply sterilisers removes all issues associated with steam quality.

A purpose-built generator will provide what is called ‘clean steam’. Since it uses water that has undergone either reverse osmosis or deionization, there are no dissolved minerals present (it is also called ‘critical water’).

When expertly installed and maintained, such a generator will eliminate a critical area where medical sterilisation problems occur, leaving you to focus on procedures and processes.

Best Practice Guide to achieving reliable and consistent high quality steam

Your Guide to achieving reliable high-quality sterilisation through the provision of dry clean steam.

Steam sterilisation in hospitals FAQs on Steam Quality

Steam provides the most reliable and efficient method of achieving effective sterilisation. It is a simple, fast and safe way to disinfect reusable equipment, but in order to be as effective as possible and reduce the potential risk of wet packs or extended sterilisation cycle times, a continuous supply of high-quality clean and dry steam is required. Angelo Giambrone, Business Development Manager answers your questions on steam quality in healthcare facilities.

Steam sterilisation in hospitals FAQs on reducing wet packs

Steam provides the most reliable and efficient method of achieving effective sterilisation. It is a simple, fast and safe way to disinfect reusable equipment, but in order to be as effective as possible and reduce the potential risk of wet packs or extended sterilisation cycle times, a continuous supply of high-quality clean and dry steam is required. Angelo Giambrone, Business Development Manager answers your most asked questions related to reducing wet packs in healthcare facilities.

Steam sterilisation in hospitals FAQs on Clean Steam Solutions

Steam provides the most reliable and efficient method of achieving effective sterilisation. It is a simple, fast and safe way to disinfect reusable equipment, but in order to be as effective as possible and reduce the potential risk of wet packs or extended sterilisation cycle times, a continuous supply of high-quality clean and dry steam is required. Angelo Giambrone, Business Development Manager answers your most asked questions related to clean steam solutions in healthcare facilities.

Domestic Hot Water Solutions Guide for Hospitals

Four common healthcare challenges and their cost effective solutions